Pilot is a digital hydrometer and thermometer that is placed inside a fermentation vessel during the fermentation of beer, wine, cider, mead, etc. It produces a continual log of gravity and temperature measurements without the need for human interaction or removal of a sample. By leveraging the principles of buoyancy, density, and gravity, measured and tracked with accelerometers, temperature sensors, and opensource software, it is not only possible to build such a device, but to make it accessible to tech-literate home brewers.

While traditional hydrometers sink vertically in order to measure the density of a liquid, Pilot both sinks and tilts at a specific angle in proportion to the density of the fluid its submerged in. By using a digital accelerometer, the angle of tilt is measured to a high degree of accuracy, and therefore the change of gravity can be measured over time. Temperature is also logged to both monitor the temperature over time, as well as being factored into density calculations.

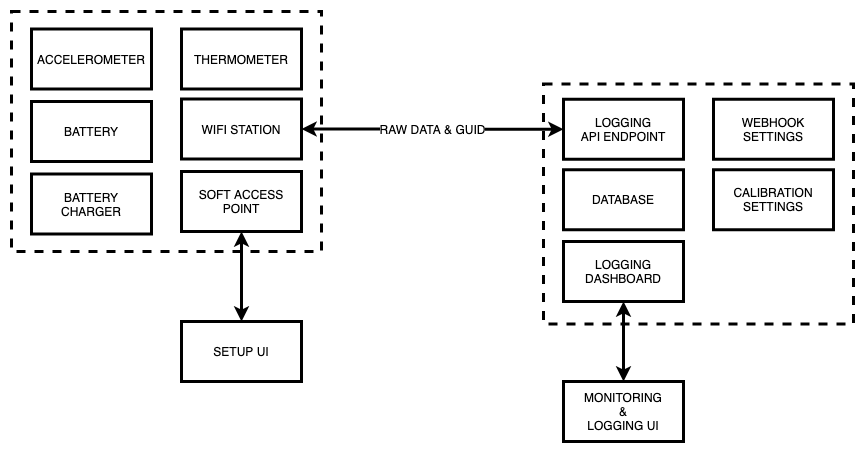

Encased and balanced in a water-tight housing, an ESP-01 module acts as the main microprocessor for Pilot. It's capabilities include reading sensor data from an I2C (inter-integrated circuit) bus, calling API (application program interface) endpoints via WIFI, hosting webpages as a soft access point, and consuming very little power by using a "deep sleep" mode. Along with the ESP-01, an I2C 3-axis accelerometer, I2C temperature senor, battery, and battery charger, make up the rest of the necessary hardware.

Fat-marker sketch of the Pilot technology ecosystem

After construction, individual calibration is necessary for each device as they all have slightly different characteristics. This is done by using regression to find an equation that explains the correlation between measurements taken from a traditional hydrometer and the angle of Pilot in fluids of different densities. See iSpindle Calibration Tool. The calibration is stored on Pilot servers as "factory defaults" and is used to to adjust raw data received via the API. For ease of use, the data from Pilot is completely raw and therefore calibration adjustments can be made in the UI after its already in the hands of a home-brewer.

After calibration, in order for Pilot to log data, the ESP-01 must first be connected to the internet via WIFI. This is done via an HTML (hypertext markup language) firmware settings/setup dashboard hosted on the ESP-01 while in Soft Access Point mode. After connecting to the internet, the device can begin to send log data to the API. Along with the data, a GUID (globally unique identification) and other diagnostic data is sent. A user can log into Pilot servers by creating an account and registering the Pilot device's GUID, which attached to the hardware. This is the same GUID that will be sent along with all requests from the device.

After receiving data from the device, the Pilot API stores the data in a database, which is accessible via a the UI (user interface). This data is exportable in different formats and future versions will give the option of setting up a webhook to allow for users to build out their own infrastructure/monitoring tools.

On the market today is the Tilt Hydrometer (formally Brewometer), a “free floating digital hydrometer and thermometer for continuous real-time monitoring.” It pairs with an iOS or Android app or a Raspberry Pi running Tilt Pi via Bluetooth and it’s through this connection that it is able to connect to the internet to do things like post logs to Google Sheets. There isn’t a lot of information about how Tilt works or how it’s built, however, more information can be found in U.S. Patent #US20140260607A1.

The “free floating” bit of marketing copy might be to distinguish the Tilt from the Brew Perfect (formally Beer Bug?), which I think might have been rebranded or is possibly no longer in business. With the Brew Perfect, a submersible “torpedo” is attached to the device and hung into the fermentation vessel. I believe the device uses the relative weight to measure the buoyancy of the torpedo to determine the density and gravity of the liquid. Combined with a temperature probe, the kit logs data to a proprietary app via WiFi.

In the opensource world exists the iSpindel (and other variants thereof). This is a well-documented digital hydrometer and thermometer. The principle behind the iSpindle is theoretically similar to the Tilt: a change in buoyancy will cause the unit to tilt (rather than to only rise and sink like a traditional hydrometer or the Brew Perfect) in proportion to the sugar content of the liquid. By using an accelerometer and a thermometer, the gravity of the liquid can be calculated.

Thanks to the community behind the device, it’s this solution where I find the most inspiration. It uses easily accessible opensource software and hardware and relies on a “perform” PET bottle for its housing.

There a HomeBrew Talk thread following along with it’s development that should be helpful for troubleshooting, but the overall design theory is relatively straightforward. My first approach will be to build a slightly pared-down implementation of the iSpindel.

.png?alt=media&token=fec997fe-6ef0-4195-a5c8-60a1279cf300)